Wholesale direct supply to help your furniture business grow

Smooth, durable, and designed to handle any load—our furniture drawer slides deliver unmatched performance and reliability.

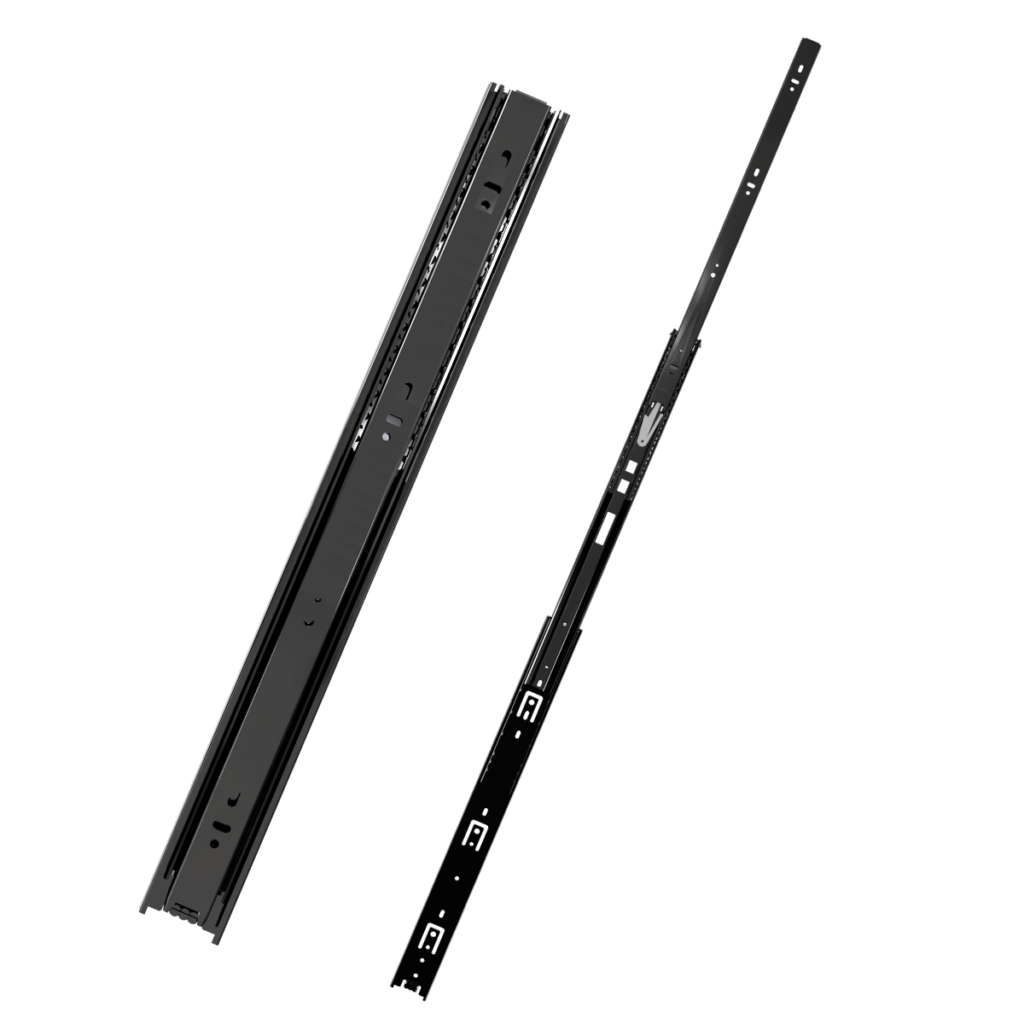

furniture drawer slides

Top Ranking Products

Do you looking for kitchen cabinet supplier

PA Home is a global leader in China’s full home customization field.

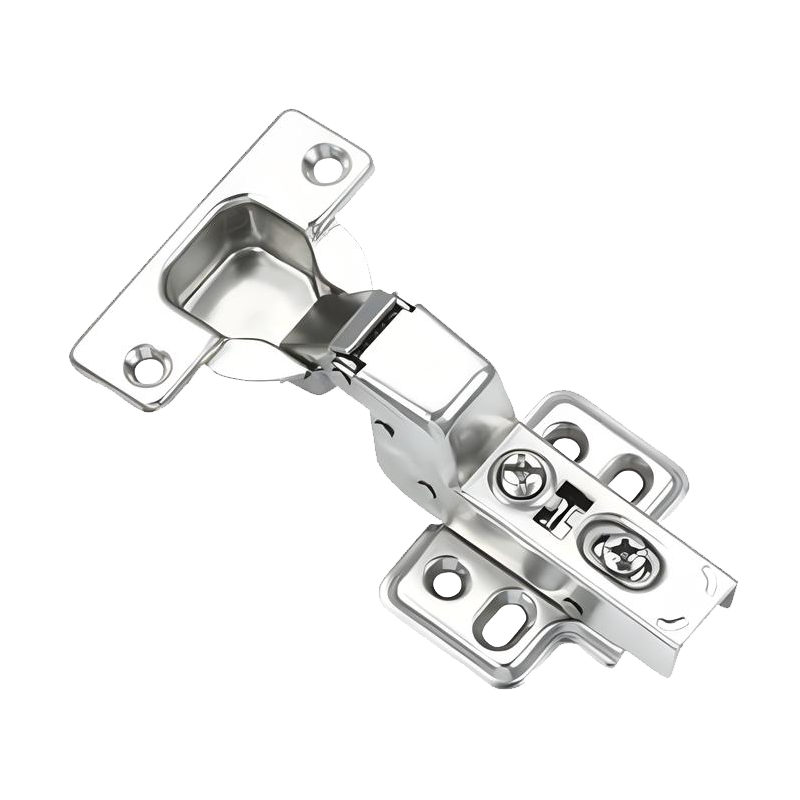

Main Products: PA Home produces kitchen cabinets, wardrobes, bathroom vanities, doors, and windows.

drawer slides for cabinets

Special Features

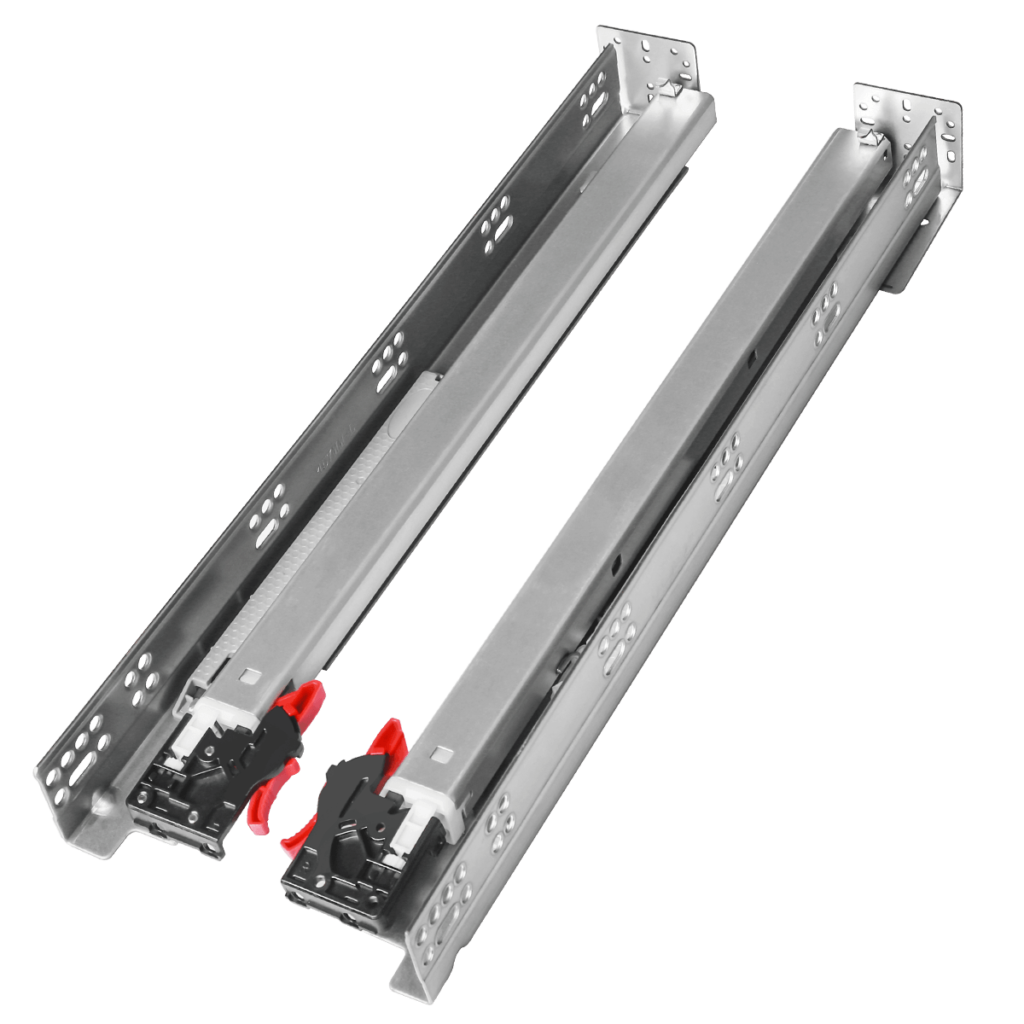

Soft Close

- Quiet and smooth: The drawer makes less noise when closing, and there is no “bang” sound, which is very suitable for homes or workplaces that require a quiet environment.

- Extend the service life: Reduce the impact force and wear of the cabinet and furniture drawer slides, and extend the service life.

- Improve the use experience: It is more comfortable to use and avoids the discomfort caused by rough closing of the door

- Improve safety: Prevent children or the elderly from pinching their fingers due to excessive force when closing the drawer.

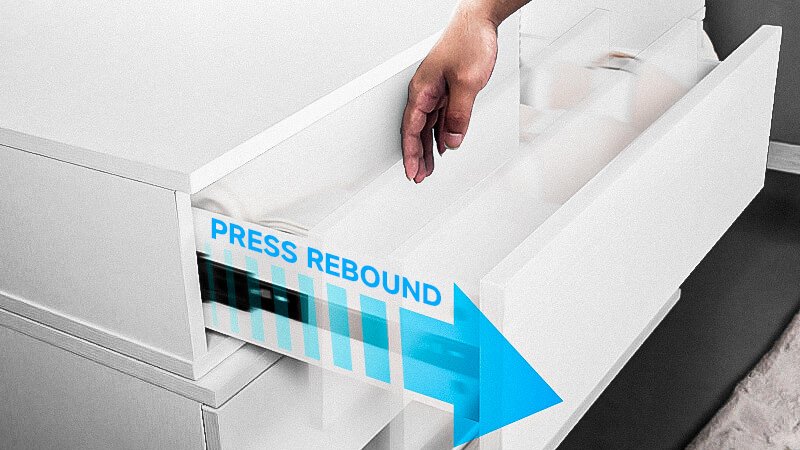

Push to Open

- Aesthetics: The traditional handle design is removed, making the furniture look more concise and modern, especially suitable for home designs that pursue a simple style.

- Convenience: No handle is required, and it can be operated with one hand, which is particularly convenient for those occasions where two hands are needed to hold things, such as the kitchen.

- Space-saving: Since there is no handle, it is suitable for places with relatively small spaces, such as small kitchens, narrow cabinets, etc.

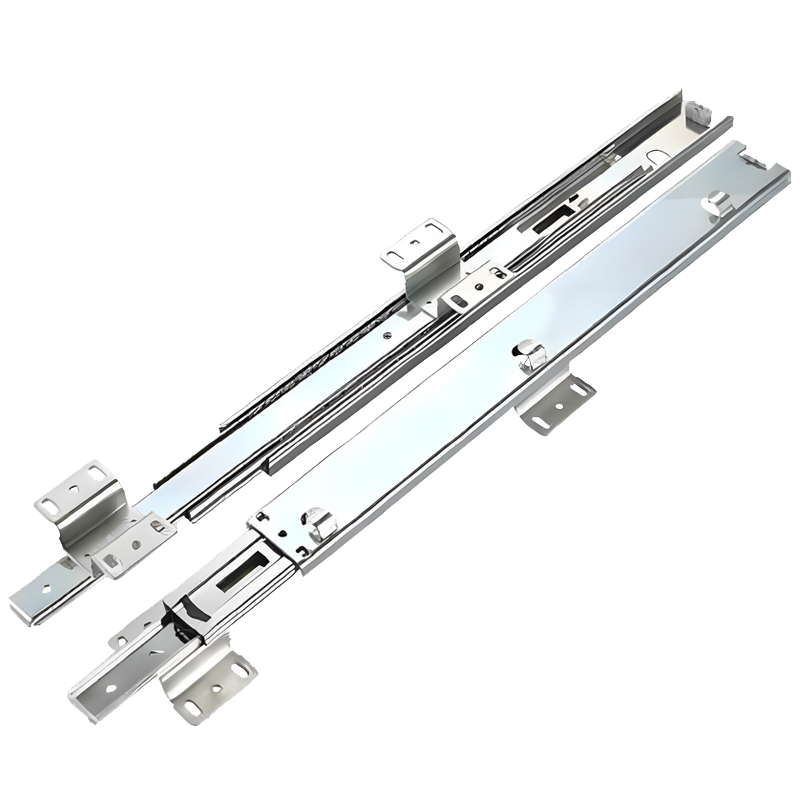

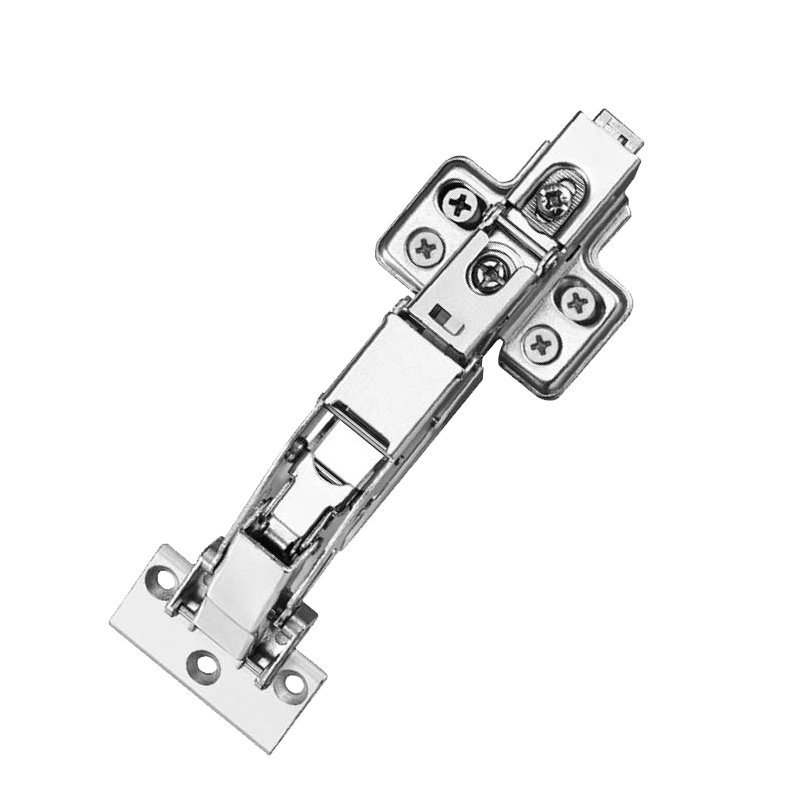

Ball bearing

High-quality ball bearing design for extremely smooth and almost silent sliding

kitchen cabinet drawer slides

Material selection

———— We mainly use Q235 cold rolled steel and also make stainless steel furniture drawer slides ————

| Performance Indicators | Wear resistance | Service life | Carrying capacity | Corrosion resistance | Cost |

|---|---|---|---|---|---|

| Q195 Cold Rolled Steel | Generally, suit light load. | Shorter, suit light household use. | Light duty. | Generally, suit indoor dry environment. | Suit projects with limited budget. |

| Q235 Cold Rolled Steel | Excellent, suit high-frequency use. | Longer, suit frequent use and heavy loads. | Medium to heavy-duty load. | Good, suit higher corrosion resistance environments. | Higher, but offers better performance and long-term value. |

| Advantage Analysis | Q235 is more suitable for long-term use and has stronger wear resistance. | Q235 is more durable and has a longer service life. | Q235 can bear greater weight and provide better stability. | Q235 has slightly better corrosion resistance and is suitable for a variety of environments. | Although the price is higher, Q235 provides higher cost performance and long-term use value. |

Serve

Wholesale prices available

Support MOQ

You may be interested

What are the three common types of cabinet drawer slides?

The three most common types of cabinet drawer slides are:

Roller Slides: These use small pulleys to allow the drawer to slide smoothly. They are generally more economical but have lower load-bearing capacity and durability.

Ball Bearing Slides: These use ball bearings to reduce friction, providing a smoother and quieter sliding experience. They have a higher load-bearing capacity and a longer lifespan, making them suitable for highly loaded drawers.

Heavy Duty Slides: These are designed to withstand heavier loads, are usually made of sturdy metal materials, and have a higher load-bearing capacity and durability, making them suitable for use with heavier drawers or in harsh environments.

How does furniture drawer slides work?

Furniture drawer slides provide smooth sliding support between the drawer and the cabinet, ensuring the drawer can open and close smoothly. Specifically, drawer guides usually consist of the following parts:

Guide rail: This is the main part fixed to the side of the drawer and the inside of the cabinet. The rail is usually long and may be made of steel or other durable materials.

Slide assembly: The slide assembly is installed on the guide rail and usually includes pulleys, ball bearings, or balls. The slide assembly enables the drawer to move smoothly on the track and reduce friction.

Guide mechanism: The guide mechanism helps maintain the stability of the drawer on the track and prevents the drawer from shaking left and right or falling off the track. This can be achieved through designed grooves, slides, or guide brackets.

When in use, when the drawer is pulled out or pushed in, the slide assembly moves on the track, reducing the friction between the drawer and the track, and making the drawer open and close more smoothly and quietly. Different types of guides (such as pulley guides, ball bearing guides, and heavy-duty guides) optimize the sliding performance of the drawer through different structures and materials to meet different usage needs.

What are the rails on drawers called?

The “tracks” on a drawer are often called drawer rails. These rails include:

Drawer Rails: Fixed to the sides of the drawer and inside the cabinet, used to support the sliding of the drawer.

Rail Bars: Sometimes also used to refer to the metal bars in the drawer rails that provide structural support.

Sliding Rails: Refers to the sliding part of the drawer that allows the drawer to slide in and out smoothly.

These rails ensure the smoothness and stability of the drawer when opening and closing.

What are the wheels on a drawer called?

The “wheels” on a drawer are often called pulleys or rollers. They are part of the drawer rail system and are responsible for reducing friction between the drawer and the rails, allowing the drawer to slide smoothly. These pulleys or rollers are sometimes called:

Rollers: These small wheels are installed on the side of the drawer to help the drawer slide on the rails. Pulleys are usually made of plastic or metal.

Ball Bearings: Some drawer systems use ball bearings instead of traditional pulleys, which can further reduce friction and improve sliding smoothness and durability.

Balls: In the case of ball bearings, there are small balls on the drawer that roll on the rails to help achieve a smooth glide.

The purpose of these components is to enhance the user experience of the drawer, making it easier and quieter to open and close.