Various Odels

Furniture Slide Rails

CenSo has 15+ years of experience manufacturing drawer slides. We provide various models of furniture slide rails (Furniture drawer slides, Pocket door slides, Table extender slides) to meet different application needs. Our drawer slides include soft-close, locking, and push-to-open models.

Furniture Slide Rails Product Catalog

Custom Drawer Slide Options

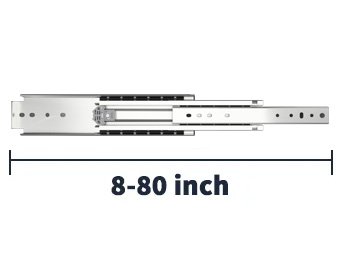

Custom Size of Slide Rail

CenSo offers custom slide sizes from 8 inches to 80 inches, as well as rail width, thickness, and other customizations related to rail size.

Custom slide function

CenSo provides customized push to open, locking, soft close mechanisms that allow you to fully extend your storage compartments for easy access.

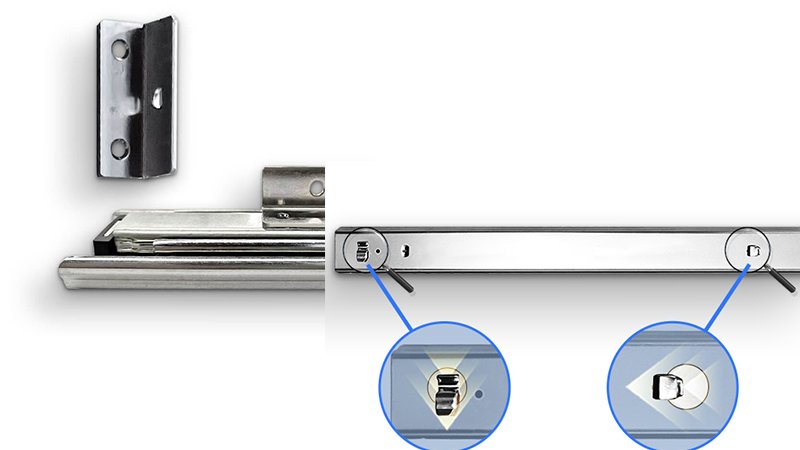

Custom structure of slide rail

We provide customization of installation methods, hole positions, level of travel, and other contents related to the slide rail structure.

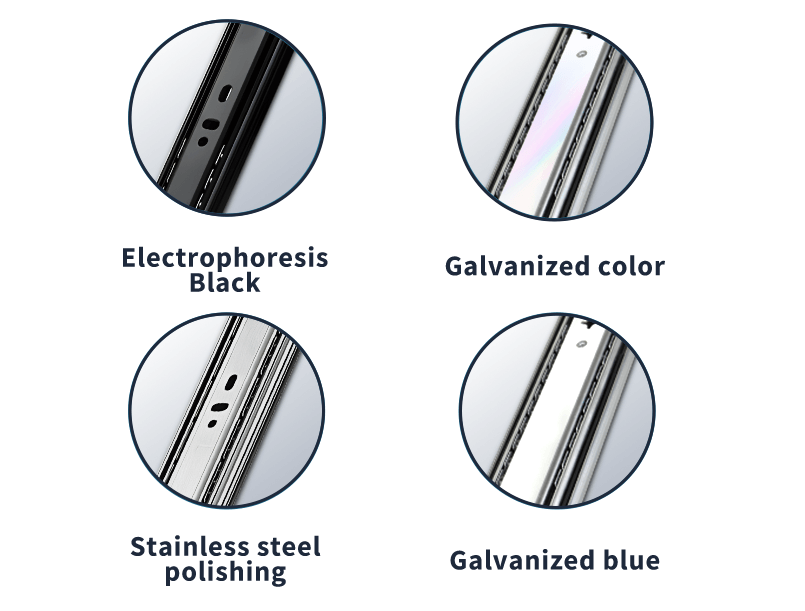

Custom Material of Slide Rail

CenSo offers customized slide rail material options, including 304 and 316 stainless steel, and can customize plate thickness, surface treatment, and other related content.

Why Choose CenSo

- Made of high-quality Q235 cold-rolled steel

- Full-load pull-out test 50,000 times

- Salt spray test 48 hours

- Production automation rate 80%+

- 130+ production equipments

- Factory area 12,000 square meters

CenSo is Your Best Partner

Distribution Cooperation

CenSo Hardware is a one-stop purchasing platform for hardware products. Let CenSo become your distribution partner to solve your hardware accessories procurement worries, simplify your supply chain management, and improve sales efficiency.

Custom Solution

CenSo Hardware provides tailor-made hardware products, customizing suitable slide rails, hinges and other hardware accessories according to project requirements, providing customers with accurate, efficient and practical product solutions.

OEM & ODM

CenSo Hardware provides comprehensive support from design to production, whether it is customized brand logo, unique design or functional adjustment, we can meet your needs to ensure your product uniqueness and market differentiation.

Contact us by email

Contact drawer slide manufacturers today if you have any questions about our products or have a particular project that you would like us to advise you on.

Address: Bld 7, Meiju LBME center, Lvjing Rd., Foshan, Guangdong, China

Phone/WhatsApp: (+86)18126638650

Email: info@censohardware.com

FAQ

What is the sliding part of a drawer called?

The sliding part of a drawer is often called a “slide” or “runner.” In a slide system, the specific sliding parts include:

1. Slide: The main component of the entire slide system, usually with two tracks fixed to the side of the drawer and the inside of the cabinet. Slides can be straight or have curves to accommodate different opening and closing needs.

2. Rollers/sliders: These are small parts installed on the slide that can reduce friction and allow the drawer to slide smoothly. Rollers are usually round and sometimes use steel balls or rollers to reduce friction.

3. Guide rails: Another component of the slide that guides and supports the drawer to keep it stable when opening and closing.

4. Damper: Some slide systems are equipped with dampers or buffers that can slowly slow down the drawer when closing, preventing banging sounds and excessive wear.

These components work together to ensure smooth and stable movement of the drawer.

How do I know what drawer slide to buy?

When choosing a drawer slide, you can consider the following factors:

1. Drawer load: Determine the maximum weight that the drawer needs to bear, and choose a slide model and load-bearing capacity that matches it.

2. Slide size: The length of the selected slide should be equal to the length of the drawer. If you can’t find the right size, you can choose a slide that is slightly shorter than the drawer, but never too short.

3. Slide type: Choose a pulley type, ball bearing type, straight rail type, etc., according to the smoothness of opening and closing and the noise requirements.

4. Drawer full opening function: If the drawer needs to be fully opened, choose a slide that supports full extension.

5. Installation method: Check the installation method of the slide to make sure it fits your cabinet structure.

6. Buffering function: If you need a quieter opening and closing experience, you can choose a buffered closing drawer slide.

7. Locking function: If you need to fix the extended drawer slide, such as to prevent the drawer from sliding out during vehicle driving, then you need to purchase Locking drawer slide.

What makes drawers slide better?

1. Choose high-quality slides: Choose high-quality slides, especially ball slides, which usually have better-sliding performance and longer service life.

2. Regular maintenance and cleaning: Clean the dust and debris on the slides regularly to prevent them from causing friction or jamming. Use a suitable lubricant (such as silicone oil or a special slide lubricant) and apply it to the slides and rollers to reduce friction and make the drawer slide more smoothly.

3. Adjust the slides: Make sure the slides are installed correctly and adjusted to the appropriate position. Unbalanced or improperly installed slides may cause the drawer to get stuck or not smooth.

4. Check the load: Make sure the drawer load is within the load-bearing range of the slide. Overweight drawers may cause difficulty in sliding or damage the slides.

5. Avoid excessive pulling: Open and close the drawer gently and avoid excessive force to reduce the impact on the slide.

6. Check the alignment of the drawer with the slide: Make sure the drawer is aligned accurately with the slide. If the drawer is not aligned with the slide, it may cause jamming or not smooth.

7. Keep the environment dry: avoid water or moisture inside the slide rails and drawers to prevent the slide rails from rusting or the lubricant from becoming ineffective. Alternatively, choose stainless steel slide rails so that they can be used in humid environments or at the seaside.

.jpg)