The basic structure and working principle of Server rack rails

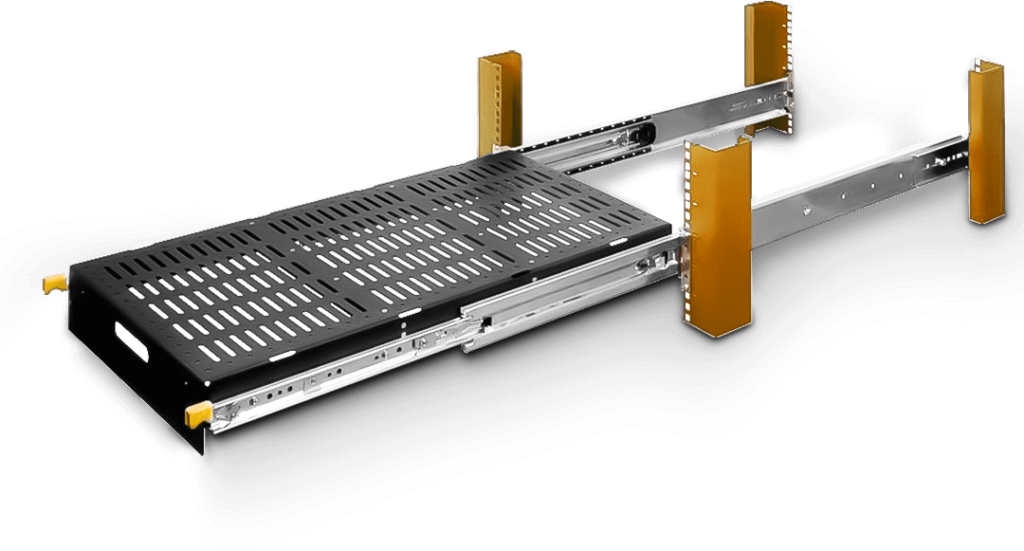

The basic structure of Server rack rails

Fixed rail server rack

Function: Fixed rail server racks are the fixed part of the server rack rail system and are usually installed on the side wall of the cabinet. They provide support and positioning for the server rack rail.

Material: Generally made of steel or aluminum to ensure strength and stability.

Mounting method: Fixed rail server racks are installed on the inside of the cabinet with screws or other fixings, sometimes with adjustment holes to accommodate cabinets of different depths.

Rack slides

Function: Rack slides are the main components that allow equipment to slide smoothly. They are connected to fixed brackets, allowing the server to slide along the track inside the cabinet.

Design: Usually includes an upper track and a lower track, sometimes a two-part track system, allowing equipment to move freely in horizontal and vertical directions.

Material: Rack slides are mostly made of wear-resistant materials, such as aluminum alloy or steel, and the surface may be hardened for increased durability.

Rollers or Ball bearing

Function: Rollers or ball bearings are installed on the slide rails to reduce friction and enable the server to slide smoothly.

Design: Rollers are usually made of high-quality plastic or metal with built-in bearings to reduce friction. Ball bearings consist of an inner ring, an outer ring, balls (or rollers), and a cage. The balls roll between the inner and outer rings for smooth movement and load support.

Adjustment function: Some slide rail systems’ rollers or ball bearings can be adjusted to ensure smooth and uniform sliding.

Locking mechanism

Function: The locking mechanism ensures the stability of the server when sliding in or out of the cabinet, preventing accidental movement and protecting the equipment and users.

Design: Common locking mechanisms include spring locks, roller locks and slider locks, which can automatically or manually lock the rail system and fix the server position.

Operation method: Users can unlock or lock the rail system with simple operations, such as pushing and pulling the locking lever or rotating the locking device.

Design Concept

The design concept of the rail system is to achieve ease of use and reliability of the equipment. The designer considers the following factors:

Load-bearing capacity: The rail system needs to be able to bear the weight of the server while ensuring stability in long-term use.

Durability: The use of high-quality materials and manufacturing processes ensures that the rails are not easily worn or deformed during long-term use.

Ease of operation: The design makes the rail system easy to operate, can be quickly installed, adjusted and maintained, and improves the user experience.

Safety: The locking mechanism and stability design ensure that the equipment does not move accidentally during use, protecting the safety of the equipment and users.

How it works

Installation

Fixed brackets are mounted on the inside of the cabinet to support the rail system. The rack slides are fixed to these brackets.

The rack slides usually consist of an upper rail and a lower rail, and rollers or sliders are installed in these rails.

Sliding

The server or equipment is mounted on the server rack rails, and the server rack rails and rollers cooperate to achieve smooth forward and backward movement.

The rollers or sliders rotate freely in the server rack mounting rails, reducing friction and ensuring that the server can slide easily to the desired position.

Locking

When sliding in or out of the cabinet, the locking mechanism of the server rack mounting rails automatically or manually fixes the position of the server to prevent the equipment from accidentally shifting during movement.

When the server is fully inserted into the cabinet or pulled out, the locking mechanism ensures that the equipment is stable and convenient for technicians to perform maintenance or inspection.

Maintenance and Adjustment

During equipment maintenance or replacement, technicians can access the components in front and behind the server by pulling them out.

The adjustable design of the server rack mounting rails allows users to adjust it according to the cabinet depth and equipment size for optimal operation and installation.

In summary, the basic structure and working principle of the server rack mounting rails reflect the modern computer room design’s focus on equipment operation convenience, safety, and space utilization. Through reasonable design and the application of high-quality materials, the server rack mounting rails not only improve the equipment maintenance efficiency but also ensure the stability and safety of the computer room environment.

Application advantages of server rack rails in equipment maintenance

The application of server rack rails in server maintenance and overhaul has brought many significant advantages. Here’s a closer look at how server rack rails simplify the equipment maintenance process, reducing repair time and operational complexity:

quick access

Simplified operation: The server rack rails allow technicians to pull the server out of the cabinet without disassembling the cabinet. This makes accessing the front and back of the server much more straightforward.

Reduced physical labor: By sliding the server, rather than removing it completely, the physical force that needs to be exerted is reduced, making the operation less complex and labor-intensive.

Improve maintenance efficiency

Reduced downtime: Technicians can quickly slide servers for troubleshooting, component replacement, or upgrades, reducing equipment downtime.

Convenient inspection: The server rack rails allow technicians to easily inspect internal server components such as hard drives, memory modules, and power supply modules without complicated disassembly procedures.

Reduce operational risk

Reduce the risk of damage: The server rack mounting rails ensure that the server will not tilt or fall during movement through stable support and locking mechanisms, thereby reducing the risk of equipment damage caused by improper operation.

Prevent accidental movement: The locking mechanism can effectively prevent accidental movement of equipment during maintenance, protecting the safety of technicians and equipment.

Optimize space utilization

Space management: The server rack rail is designed so that servers can slide within the cabinet without completely removing the equipment. This approach allows technicians to maintain a high density within the cabinet while still performing maintenance efficiently.

Flexible configuration: Since the server rack rails allow the server to slide forward and backward in the cabinet, technicians can easily adjust the position of the equipment and optimize the space layout to adapt to maintenance needs.

Improve operational flexibility

Adapt to different equipment: Rack slides usually have adjustment functions and can adapt to cabinets of different depths and servers of various sizes. This flexibility allows technicians to easily handle different types of equipment and configurations.

Modular design: The modular design of the rack slides makes maintenance operations more flexible, and technicians can quickly replace or upgrade components without the need for complicated disassembly and assembly.

Simplify maintenance processes

Quickly replace components: By sliding the server, technicians can easily access and replace key components such as hard drives, memory modules, and power modules without disassembling the entire device.

Efficient troubleshooting: The rack slides allow technicians to quickly locate the fault point, inspect and repair it, shortening troubleshooting time.

Improve maintenance safety

Safety locking: The locking mechanism equipped with the server rack rail ensures that the server remains stable during maintenance, reducing the occurrence of misoperation and accidents.

Safe operation: Technicians can perform maintenance without bending or exerting excessive force, reducing physical burden and potential safety risks during operation.

Support remote maintenance

Integrated technology: Some advanced server rack rails integrate remote maintenance technology, such as remote control of the sliding mechanism, allowing technicians to perform equipment maintenance without entering the computer room.

Automation features: Modern server rack rails may be equipped with automation features that can automatically pull or push equipment into the cabinet through remote operation, further improving maintenance efficiency.

Summarize

The application of server rack mounting rails in equipment maintenance brings significant advantages. They improve maintenance efficiency, reduce operational risks, optimize space utilization, and enhance maintenance flexibility and security by simplifying server access and operations. Through these advantages, the server rack mounting rails effectively reduce maintenance time and operational complexity, making machine room management and equipment maintenance more efficient and reliable.

Improve the space utilization of the computer room: the design and layout of the server rack rails

The rack slide plays a vital role in computer room space management. It helps improve the space utilization of the computer room by optimizing equipment layout and increasing equipment density. Here is a detailed discussion of how the rack slide achieves these optimizations:

Optimize equipment layout

Compact configuration: The slide rail system allows servers to slide smoothly within the cabinet, reducing the gaps between devices so that the devices can be arranged more compactly. This compact configuration helps fit more equipment in a limited space.

Flexible adjustment: The adjustable design of the slide rail system allows the equipment to adjust its position as needed, thereby optimizing the layout inside the cabinet. Technicians can adjust the arrangement of equipment according to actual needs to ensure optimal use of space.

Increase device density

Reduce cabinet gaps: The slide rail system reduces the gap between the equipment and the cabinet, allowing the cabinet to accommodate more equipment. Close arrangement of equipment can significantly increase the equipment density of the computer room.

High-density deployment: By achieving higher device density within the cabinet, the slide rail system helps the computer room improve computing and storage capabilities, saving valuable computer room space while maintaining efficient operation of the system.

Ensure good air circulation

Ventilation design: The design of the rack slide helps maintain proper spacing between servers, thereby optimizing airflow. Good air circulation is key to ensuring effective cooling of the server.

Avoid obstruction: The mounting position and design of the rack slide can avoid obstructing the airflow in the cabinet, reducing the risk of overheating and ensuring the stability and performance of the server.

Improve operability

Convenient maintenance: By sliding the server, technicians can easily access the equipment inside the cabinet without completely removing the server. This design makes maintenance operations more convenient, thereby reducing operation time and occupying space in the machine room.

Quick access: Slide rails allow servers to slide out of the cabinet, allowing technicians to quickly access and perform maintenance or replace parts. This convenient operation improves overall work efficiency.

Enhance space utilization flexibility

Modular design: The modular design of the slide rail system allows the internal layout of the cabinet to be adjusted according to needs. The modular slide rail system can adapt to different sizes of equipment and cabinet depths, providing greater space utilization flexibility.

Dynamic adjustment: According to the actual needs of the equipment and changes in the computer room, the slide rail system can support dynamic adjustment of the layout to improve space adaptability and utilization.

Support high-density cabinets

High-density cabinet design: The slide rail system supports high-density cabinet design, allowing the cabinet to accommodate more servers and equipment. In this design, the optimized layout of the slide rails can effectively manage space while ensuring the stability and safety of the equipment.

Space optimization: By rationally arranging equipment and slide rail systems, you can maximize the use of the space inside the cabinet and improve the overall space utilization of the computer room.

Summarize

The slide rail system plays an important role in improving the space utilization of the computer room. By optimizing equipment layout, increasing equipment density, ensuring good air circulation and improving operability, the slide rail system not only improves the space utilization efficiency of the computer room, but also ensures the stable operation of the equipment and the convenience of maintenance. These advantages make slide rail systems an indispensable part of modern computer room design, helping to achieve efficient equipment management and operation within limited space.

Stability and safety of slide rails: the key to protecting equipment

The slide rail system plays a vital role in improving the stability and safety of the server. The following is a detailed analysis of how the slide rail achieves this goal, preventing the equipment from shaking in the cabinet and reducing the risk of physical damage:

Enhancing equipment stability

Solid support: The fixed bracket and track design of the slide rail system provide stable support to ensure that the position of the server in the cabinet will not move easily. This stable support reduces the shaking and vibration of the equipment and maintains the stability of the equipment.

Uniform load distribution: The design of the slide rail makes the weight of the server evenly distributed in the cabinet, thereby reducing the risk of local overload. Uniform load distribution helps to keep the equipment balanced and prevent tilting or instability.

Prevent equipment from shaking

Locking mechanism: The locking mechanism equipped with the slide rail system ensures that the server remains stable when sliding in or out of the cabinet. The locking device automatically fixes when the equipment reaches the predetermined position to prevent the equipment from shaking during maintenance or operation.

Shock absorption function: Some slide rail systems are designed with shock absorption functions, such as elastic pads or buffering materials, which help absorb vibrations from inside the cabinet and reduce the impact on the equipment.

Reduce the risk of physical damage

Reduce human error: The stability design of the slide rail system reduces the risk of equipment damage caused by improper operation. The locking mechanism and smooth sliding process reduce the possibility of equipment falling or tilting during operation.

Protective devices: The slide rail system is usually equipped with protective devices, such as anti-collision strips or edge protection, to prevent the server from colliding with other equipment or structures in the cabinet during sliding, thereby reducing the risk of physical damage.

Provide a safe operating environment

Safe operation: The slide rail system allows the equipment to slide smoothly in and out of the cabinet, reducing the complexity of operation in a small space. This design reduces the possibility of accidents during maintenance by operators and ensures safe operation.

Reduce operational risks: The design of the slide rail system reduces the operational risks of the server during movement, avoiding the equipment tilting, falling or collision problems that may be encountered in traditional installation methods.

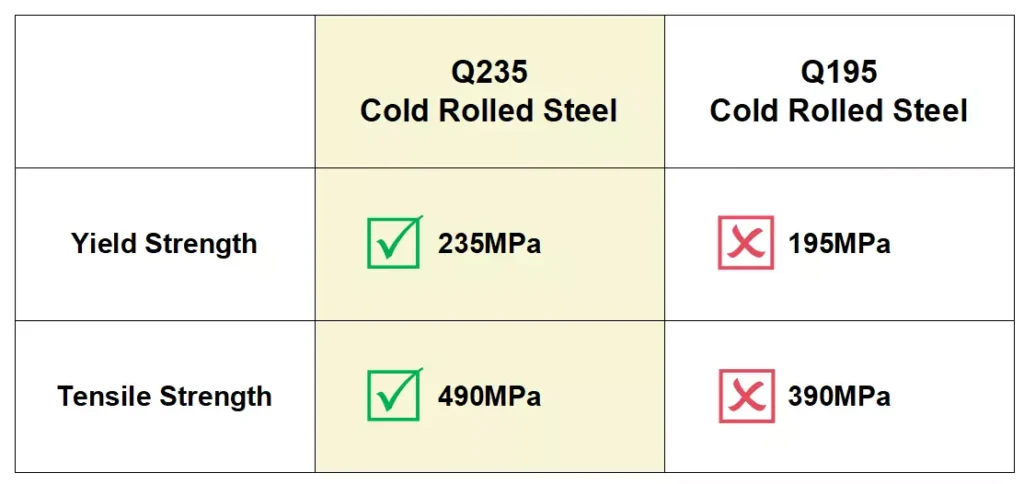

Durable materials and design

High-strength materials: The slide rail system uses high-strength materials such as steel or aluminum to ensure stability when bearing the weight of the equipment and operating loads. These materials improve the durability of the slide rail system and reduce stability problems caused by wear or deformation.

Precision manufacturing: The rail system is precision manufactured and strictly controlled to ensure the precise docking and stability of the rail assembly, thereby effectively supporting the equipment and reducing vibration.

Adaptable design

Adapt to different equipment: The adjustable design of the rail system can adapt to servers of different sizes and weights, ensuring that each device can obtain proper support and stability. This adaptable design enables the rail system to effectively protect various types of equipment.

Summary

The rail system has significant advantages in improving server stability and safety. By providing stable support, reducing equipment shaking, reducing the risk of physical damage, and enhancing operational safety, the rail system effectively protects the equipment in the cabinet. In addition, durable materials and precision design further ensure the long-term stability of the rail system. These features make the rail system a key component for protecting equipment, ensuring the stability of the computer room operation and the long life of the equipment.

If you want to know more about CenSo’s custom rail, you can click Custom Drawer Slides, or you can click on Custom Drawer Slides – CenSo’s Custom Slide RailProcess and Technical Support Services to learn more about our custom process.