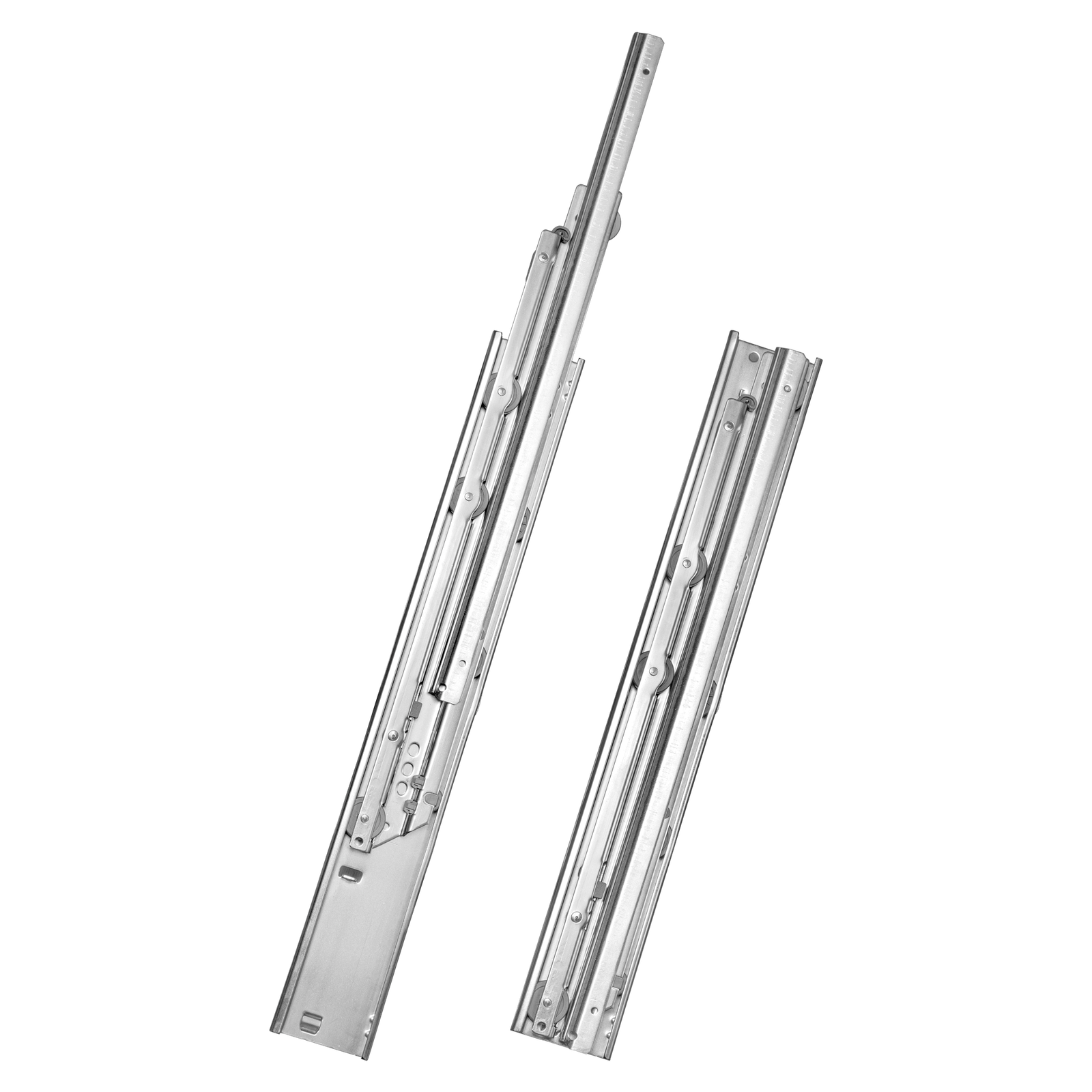

Stainless Steel Roller Bearing Drawer Slides

Refrigerator Drawer Slide Rail

- Feature: -40℃ ~ 75℃

- Size Range: 14″ to 26″

- Material: Stainless Steel 304

- Installation Gap: 17±0.3mm

- Loading Capacity: 55KG

- Material Thickness: 1.5*2.0*1.5mm

- Level of Travel: Full Extension

If you need customization, please contact us (+86)18126638650 or email info@censohardware.com

Tech Specs

—— Click on the customization option you need and contact us! ——

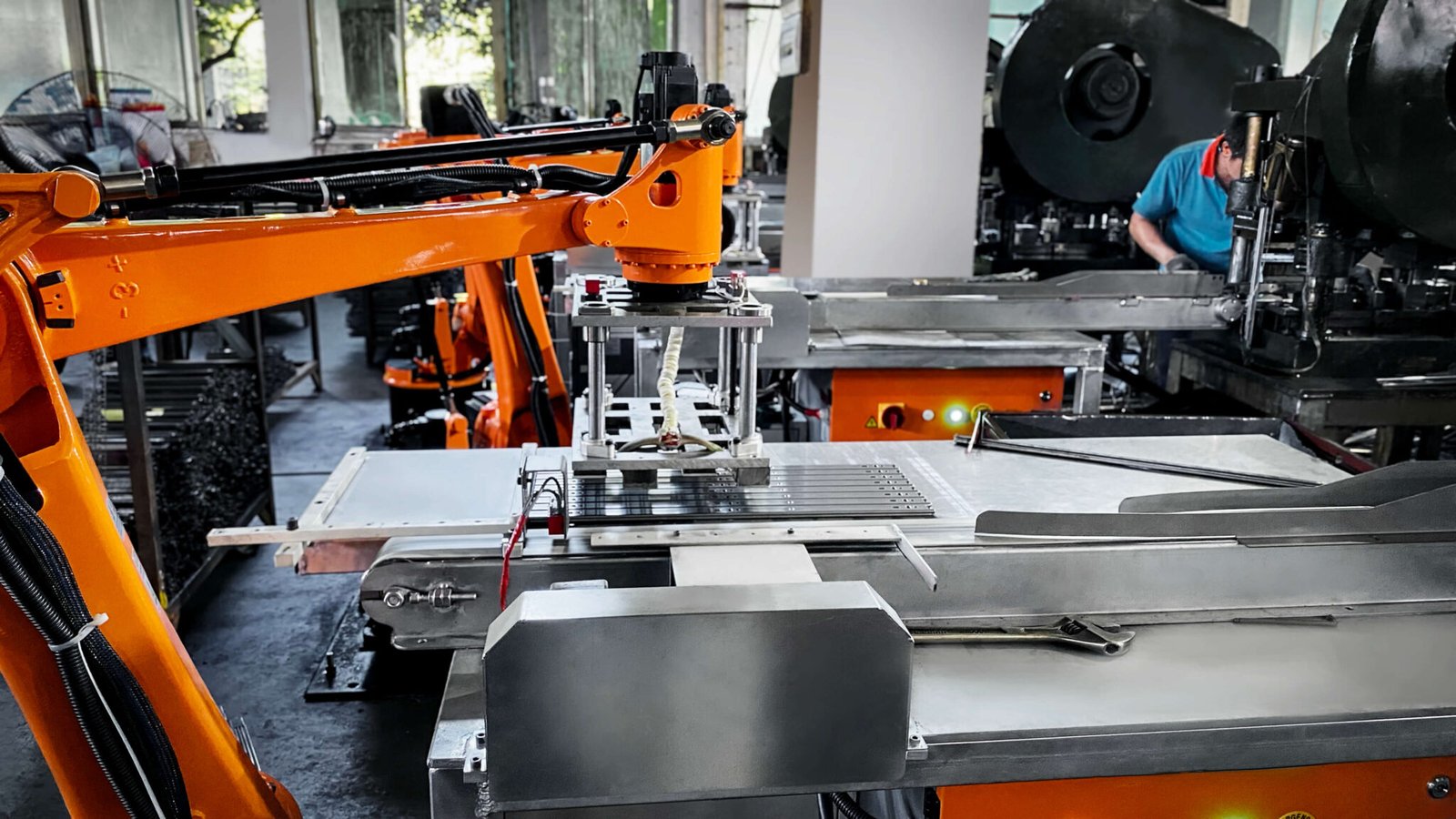

Benefits of Partnering With CenSo for Drawer Slides

- Excellent Technology: Our 20+ R&D engineers use 15+ years of design and development experience to develop solutions for your project.

- Flexible Design: Besides providing a wide range of off-the-shelf products, we can customize various slide contents to adapt them to your project plan.

- Continuous Service: The entire CenSo team is committed to being your best partner. We will provide follow-up technical support on slides to ensure that your project is worry-free.

- Quality Assurance: Our drawer slides will be tested for 50,000 pulls and pulls at full load and 48 hours of salt spray test. We will also add corresponding tests according to the slides of different applications

faq

What is a Refrigerator Drawer Slide Rail?

A refrigerator drawer slide rail is a sliding device used in the drawer system inside a refrigerator, designed to make the drawer open and close more smoothly. It is usually made of durable metal or plastic material that can withstand the pressure and weight of daily use, ensuring that the drawer can be pulled out smoothly and closed securely.

Why don't refrigerator drawer slide rails use ball bearings?

1. Not suitable for low-temperature environments

Ball bearings may have problems with increased viscosity of lubricating oil in low-temperature environments, resulting in poor sliding performance. The temperature inside the refrigerator is often at a low level, which may make the lubricating oil of the ball bearing too viscous at low temperatures, affecting the smoothness of the bearing. In contrast, refrigerator drawer slide rails made of ordinary slide systems, such as steel or plastic slides, have more stable performance in low-temperature environments and are not affected by temperature changes.

2. Moisture resistance

Ball bearings require more stringent sealing and lubrication conditions, and in a humid environment such as a refrigerator, moisture may penetrate the bearing. This not only easily causes the bearing to rust, but also may affect the sliding performance. Traditional slide rail designs generally use a simpler structure to avoid such problems and reduce damage caused by moisture.

stainless steel ball bearing drawer slides or stainless steel Roller Bearing Drawer Slides?

1. Completely different usage scenarios

In the use of industrial freezers, it is often necessary for the drawer slides to be able to withstand lower temperatures. Therefore, stainless steel drawer slides have become the first choice for industrial freezer manufacturers. The working conditions of the Drawer slide rails at low temperatures are different from those at normal temperatures. Therefore, a structure that is more suitable for low-temperature operation is needed. Thus, the design structure of stainless steel Roller Bearing Drawer Slides emerged. The structure of the ordinary stainless steel Roller Bearing Drawer Slides is more suitable for general drawers, while the stainless steel Roller Bearing Drawer Slides are designed based on the structure of commercial freezers, which is more in line with the working environment and usage scenarios of industrial freezers and saves space to a greater extent. Improve the utilization efficiency of industrial freezers.

Contact Us