Stainless Steel Drawer Slides

Heavy Duty Stainless Steel Locking Drawer Slides W2053D

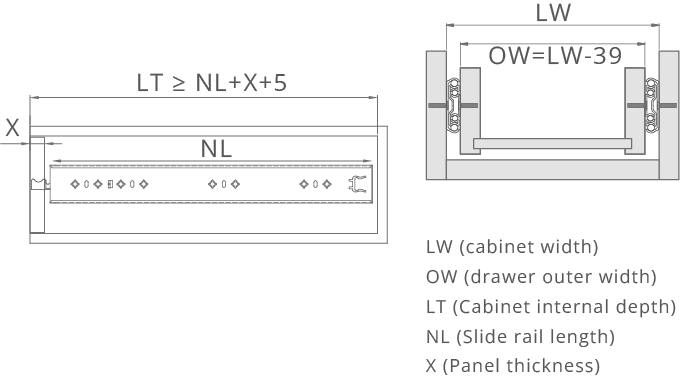

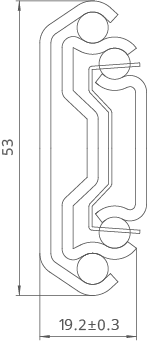

- Width: 53mm

- Size Range: 10″ to 60″

- Material: Stainless Steel 316

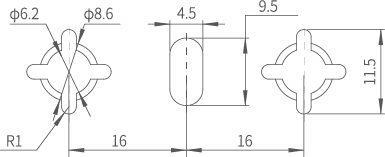

- Installation Gap: 19.2±0.3mm

- Loading Capacity: 120KG/18″ (450mm)

- Material Thickness: 2.0*2.0*2.0mm

- Level of Travel: Full Extension

If you need customization, please contact us (+86)18126638650 or email info@censohardware.com

Tech Specs

—— Click on the custom options for the heavy duty stainless steel locking drawer slides you need and contact us! ——

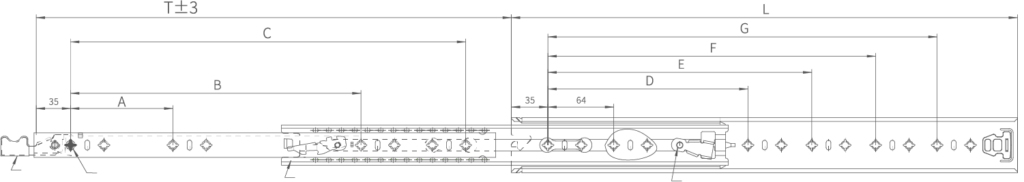

Size Chart

| Model | L | T | A | B | C | D | E | F | G |

|---|---|---|---|---|---|---|---|---|---|

| 12" | 300 | 300 | 192 | / | / | 192 | / | / | / |

| 14" | 350 | 350 | 256 | / | / | 224 | / | / | / |

| 16" | 400 | 400 | 96 | 288 | / | 288 | / | / | / |

| 18" | 450 | 450 | 128 | 320 | / | 192 | 320 | / | / |

| 20" | 500 | 500 | 160 | 384 | / | 224 | 384 | / | / |

| 22" | 550 | 550 | 160 | 416 | / | 256 | 416 | / | / |

| 24" | 600 | 600 | 192 | 480 | / | 256 | 416 | 480 | / |

| 26" | 650 | 650 | 224 | 384 | 512 | 192 | 288 | 448 | 512 |

| 28" | 700 | 700 | 224 | 416 | 576 | 192 | 320 | 480 | 576 |

| 30" | 750 | 750 | 224 | 448 | 608 | 192 | 352 | 512 | 608 |

| 32" | 800 | 800 | 224 | 480 | 672 | 192 | 384 | 544 | 672 |

| 34" | 850 | 850 | 224 | 512 | 736 | 192 | 416 | 576 | 736 |

| 36" | 900 | 900 | 224 | 512 | 768 | 192 | 448 | 608 | 768 |

| 38" | 950 | 950 | 224 | 576 | 832 | 192 | 480 | 640 | 832 |

| 40" | 1000 | 1000 | 224 | 640 | 864 | 192 | 480 | 672 | 864 |

Benefits of Partnering With CenSo for Stainless Steel Drawer Slides

- Excellent Technology: Our 20+ R&D engineers use 15+ years of design and development experience to develop solutions for your project.

- Flexible Design: Besides providing a wide range of off-the-shelf products, we can customize various slide contents to adapt them to your project plan.

- Continuous Service: The entire CenSo team is committed to being your best partner. We will provide follow-up technical support on slides to ensure that your project is worry-free.

- Quality Assurance: Our drawer slides will be tested for 50,000 pulls and pulls at full load and 48 hours of salt spray test. We will also add corresponding tests according to the slides of different applications

Contact Us