Stainless Steel Drawer Slides

Stainless Steel Drawer Slides U1035

- Width: 35mm

- Size Range: 10″ to 20″

- Material: Stainless Steel 201

- Installation Gap: 12.7±0.3mm

- Loading Capacity: 35KG/18″ (450mm)

- Material Thickness: 1.0*1.0*1.2mm

- Level of Travel: Full Extension

If you need customization, please contact us (+86)18126638650 or email info@censohardware.com

Tech Specs

—— Click on the customization option you need and contact us! ——

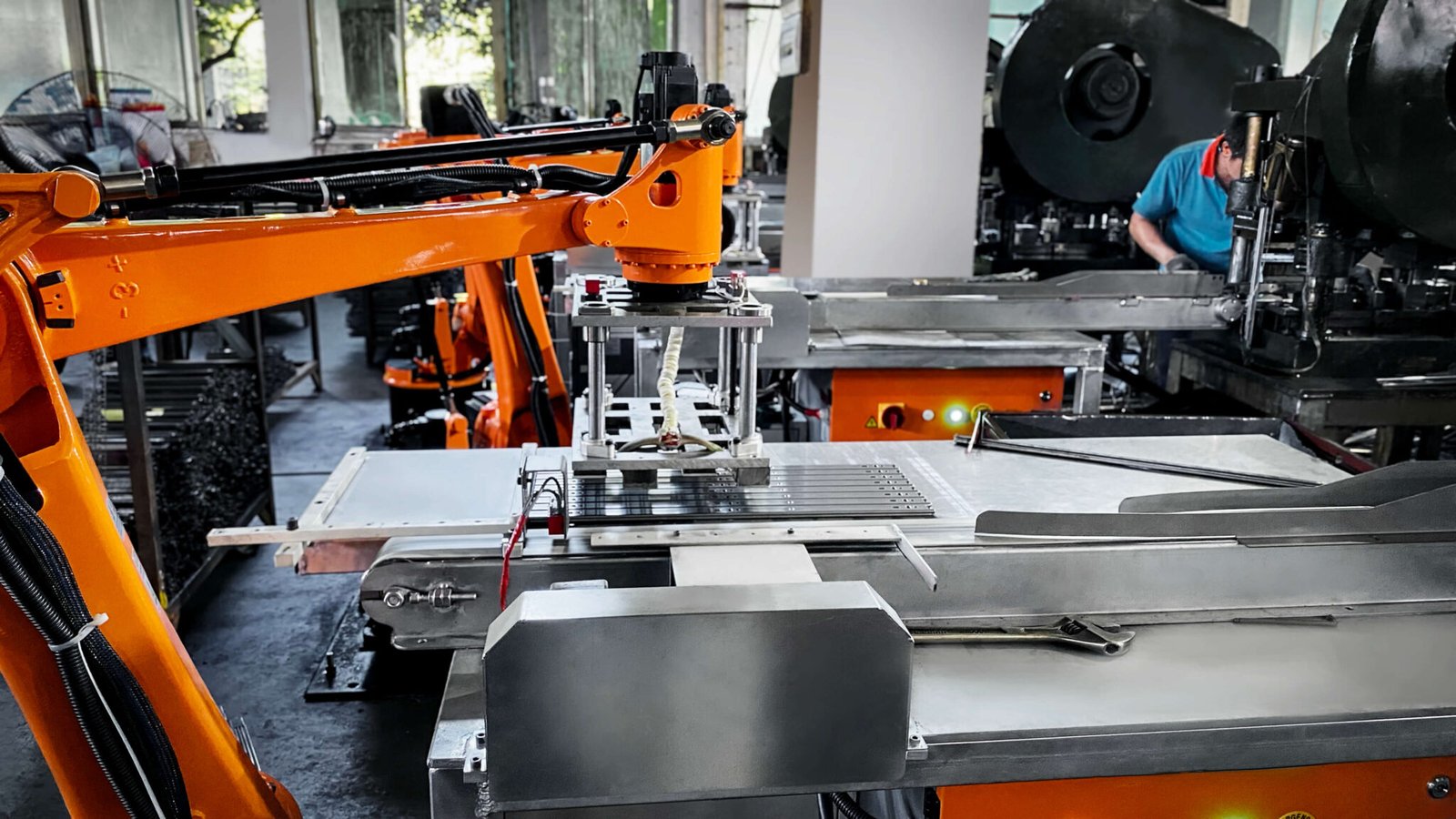

Benefits of Partnering With CenSo for Drawer Slides

- Excellent Technology: Our 20+ R&D engineers use 15+ years of design and development experience to develop solutions for your project.

- Flexible Design: Besides providing a wide range of off-the-shelf products, we can customize various slide contents to adapt them to your project plan.

- Continuous Service: The entire CenSo team is committed to being your best partner. We will provide follow-up technical support on slides to ensure that your project is worry-free.

- Quality Assurance: Our drawer slides will be tested for 50,000 pulls and pulls at full load and 48 hours of salt spray test. We will also add corresponding tests according to the slides of different applications

faq

What is the difference between 201 stainless steel drawer slides and other stainless steel materials?

Stainless steel 201 is a type of chromium-nickel stainless steel with good corrosion resistance and wear resistance, but compared with 304 stainless steel, 201 stainless steel has slightly inferior corrosion resistance. 201 stainless steel is usually cheaper, so it is widely used in drawer slides, furniture accessories, and other occasions that require certain strength and durability.

What are the different types of drawer slides?

There are many types of drawer slides, each suitable for different usage scenarios and needs. Here are some common types of drawer slides:

1. Side Mount Drawer Slides

Description: This type of slide is installed on the side of the drawer and is commonly found in home and office furniture.

Features:

Full Extension: Allows the drawer to be fully pulled out, facilitating full access to the inside of the drawer.

Half Extension: The drawer can only be pulled out halfway, suitable for situations where partial access is required.

Applicable scenarios: Suitable for most standard drawers, and the installation is relatively simple.

2. Bottom Mount Drawer Slides

Description: This type of slide is installed on the bottom of the drawer and is suitable for designs that require more concealed slides.

Features:

Stability: Bottom mounting provides better stability and load-bearing capacity.

Hiddenness: The slide is not easy to see and is suitable for modern designs.

Applicable scenarios: Suitable for drawers with specific design requirements or occasions where space needs to be saved.

3. Roller Drawer Slides

Description: This type of slide uses rollers to reduce friction and help the drawer move smoothly.

Features:

Smoothness: Reduces friction and makes the drawer slide more smoothly.

Applicable scenarios: Suitable for light or medium-duty drawers, simple installation and maintenance.

4. Ball Bearing Drawer Slides

Description: This type of slide uses steel balls to support and guide the movement of the drawer.

Features:

Durability: Provides smooth sliding performance and high load-bearing capacity.

Full telescopic: Usually supports full telescopic design, allowing the drawer to be fully pulled out.

Applicable scenarios: Suitable for drawers of various loads, including heavy drawers.

5. Concealed Drawer Slides

Description: This type of slide is completely hidden inside the drawer, is not easy to see, and provides a neat appearance.

Features:

Concealment: The slide is completely hidden, and suitable for modern home design.

High-end design: Usually used in high-end furniture.

Applicable scenarios: Suitable for high-end furniture that requires a beautiful appearance and high functionality.

6. Track Drawer Slides

Description: Use a slide or rail system to guide the movement of the drawer, usually installed at the bottom or sides of the drawer.

Features:

Guide system: Provides stable guidance and reduces the shaking of the drawer.

Applicable scenarios: Suitable for specific designs or situations where a custom solution is required.

Can you replace drawer slides on old cabinets?

It is possible to replace the drawer slides on old cabinets. Although the process may involve some adjustments and adaptations, it is usually possible. Here are the steps and precautions for replacing the drawer slides of old cabinets:

Replacement steps

1. Evaluate the existing slides:

Check the slide type: Understand the type of current slides (such as side slides, bottom slides, etc.) so that you can choose new slides that match them.

Measure the size: Measure the length, width, and size of the existing slides to choose the right new slides.

2. Choose the new slide:

Match the type: Choose a new slide that is the same or compatible with the old slide type. If you want to change the slide type, make sure the new slide can adapt to the design of the cabinet and drawer.

Load capacity: Choose the right slide according to the weight of the drawer.

3. Remove the old slide:

Remove the screws: Use a screwdriver or electric drill to remove the screws that secure the old slide.

Remove the slide: Carefully remove the old slide to avoid damage to the drawer or cabinet.

4. Install the new slide:

Position and mark: Place the new slide in the appropriate position and mark the location of the mounting holes.

Install new slides: Screw in new slides to ensure they are aligned horizontally and securely installed.

Adjust and test: After installation, check that the drawer opens and closes smoothly. Adjust the position and alignment of the slides as needed.

5. Inspection and maintenance:

Ensure smoothness: Ensure that the new slides move smoothly without friction or jamming.

Regular maintenance: Regularly check the fixation of the slides and clean the slides of dust and debris to maintain smooth operation.

Notes

Size and matching: The size and type of the new slides must be compatible with the old slides to avoid installation difficulties or functional problems.

Cabinet structure: Check the interior of the cabinet for damage or structural problems, and repair them if necessary to ensure a secure installation of the new slides.

Professional help: If you are unsure how to choose or install the slides, you can seek help from professionals to ensure quality installation and function.

Can drawer slides be laid flat?

Drawer slides are usually not suitable for flat (i.e. horizontal placement), mainly due to design requirements and functional limitations. Here are some specific reasons:

1. Design requirements

Side slides: Usually designed to be installed on the side of the drawer, the slides are required to be perpendicular to the opening and closing direction of the drawer. If they are laid flat, it will affect the normal use of the slides.

Bottom slides: Designed to be installed at the bottom of the drawer, if they are laid flat, the slides may not be able to properly support the sliding of the drawer.

2. Functional limitations

Load capacity: The load capacity and sliding performance of the slides are designed according to their installation method. Laying the slides flat may not provide sufficient support and affect the smoothness of sliding.

Sliding direction: The design of the slides and the configuration of the rollers or steel balls are usually optimized based on the vertical installation method. Laying them flat may cause uneven sliding or jamming.

3. Installation stability

Fixing method: The installation of the slides usually relies on a vertical installation method to maintain stability. Laying the slides flat may not be easy to fix, resulting in loose installation or unstable drawers.

4. Maintenance issues

Dust accumulation and friction: Flat installation may cause the slide rail to accumulate dust and debris more easily, affecting the sliding performance and service life.

Suitable installation method

Side slide rail: Installed on the side of the drawer, usually needs to be perpendicular to the opening and closing direction of the drawer.

Bottom slide rail: Installed at the bottom of the drawer, usually also needs to maintain a vertical position to ensure stability.

Summary

Drawer slides usually need to be installed according to design requirements. Laying the slide rail flat will affect its normal function and use effect. It is recommended to install according to the installation instructions and design requirements of the slide rail to ensure the best performance and stability.

What is the easiest drawer slide to install?

The easiest drawer slides to install are usually side mount slides. These slides are relatively simple to install and work with most standard drawers. Here are a few features of side mount slides that make them easy to install:

1. Easy Installation

Fixing: Side mount slides are usually screwed to the sides of the drawer and the sides of the cabinet, making the installation process intuitive.

Adjustment Space: Side mount slides provide a certain amount of adjustment space for easy alignment and adjustment.

2. Compatibility

Universality: Side mount slides work with most types of drawers and have high compatibility.

Standardization: Many side mount slides are standardized and have a full range of accessories, making it easy to find replacements and repair parts.

3. Tool Requirements

Common Tools: Installing side mount slides usually only requires basic tools, such as a screwdriver or electric drill.

4. Sliding Performance

Smoothness: Most side mount slides provide smooth sliding performance, making them easy and comfortable to use.

Comparison of Difficulty of Other Types of Slides:

Bottom Slides: Installation requires more precision and may require more adjustments and measurements.

Ball Slides: Although they perform well, they are relatively complex to install and debug.

Hidden slides: installation is more complicated, requiring special accessories and precise installation.

Summary

If you are looking for easy-to-install drawer slides, side slides are a good choice. Its simple installation process and high compatibility make it suitable for most home and office furniture needs.

Contact Us