.jpg)

Cold-rolled Steel Drawer Slides

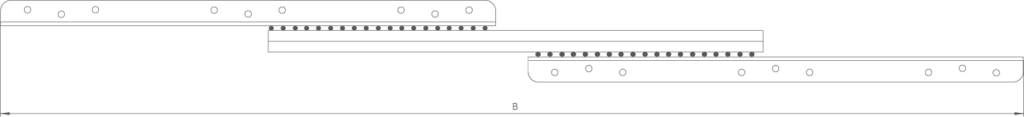

Heavy Duty Undermount Drawer Slides (Sliver) A2047

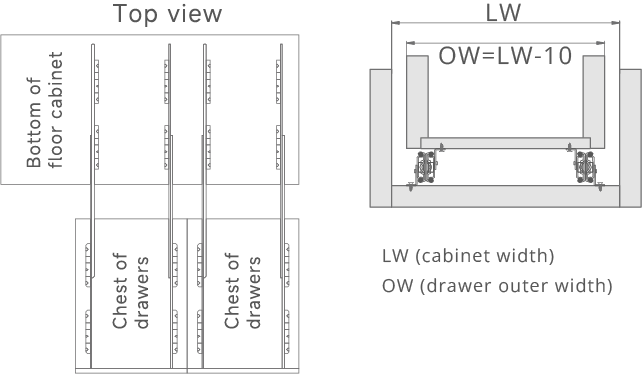

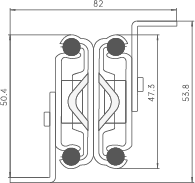

- Width: 48mm

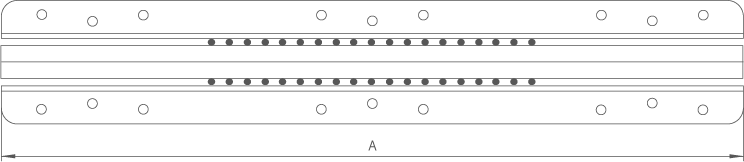

- Size Range: 400, 600, 800, 1000mm

- Material: Cold-rolled Steel

- Installation Gap: 54±0.3mm

- Loading Capacity: 120KG

- Material Thickness: 2.0*2.0mm

- Level of Travel: Full Extension

If you need customization, please contact us (+86)18126638650 or email info@censohardware.com

Tech Specs

—— Click on the customization option you need and contact us! ——

Size Chart

| A | B |

|---|---|

| 400 | 700/900 |

| 600 | 1100/1450 |

| 800 | 1500/1850 |

| 1000 | 1900/2250 |

| Support customized size | Support customized size |

Benefits of Partnering With CenSo for Drawer Slides

- Excellent Technology: Our 20+ R&D engineers use 15+ years of design and development experience to develop solutions for your project.

- Flexible Design: Besides providing a wide range of off-the-shelf products, we can customize various slide contents to adapt them to your project plan.

- Continuous Service: The entire CenSo team is committed to being your best partner. We will provide follow-up technical support on slides to ensure that your project is worry-free.

- Quality Assurance: Our drawer slides will be tested for 50,000 pulls and pulls at full load and 48 hours of salt spray test. We will also add corresponding tests according to the slides of different applications

faq

Why are my drawer slides hard to close?

There are several reasons why heavy drawer slides may be difficult to close:

- Alignment issues: The slides may not be aligned correctly, resulting in increased friction between the drawer and the rails.

- Dust and dirt: Dust or dirt may have accumulated on the slides, affecting the smoothness of the slide.

- Damage or deformation: The slides or the drawer itself may be damaged or deformed, preventing normal closure.

- Insufficient lubrication: The slides need proper lubrication, which can cause sliding difficulties.

- Overloading: The drawer may be overloaded, exceeding the load-bearing range of the slides, resulting in difficulty in closing.

How do you clean heavy duty drawer slides?

Here are the steps to clean heavy duty drawer slides:

- Remove the drawer: Gently remove the drawer from the slide to make cleaning easier.

- Clean the slide: Use a brush or vacuum to remove dust and debris from the slide. You can also wipe the slide with a damp cloth or sponge to remove stubborn dirt. Make sure the cloth is wet but not dripping to prevent moisture from seeping into the slide.

- Check and clean the balls or rollers: If the slide has balls or rollers, check for dirt and clean them with a small brush if necessary.

- Lubricate: Apply a suitable lubricant (such as silicone grease or lubricating oil) to the slide to ensure smooth sliding. Avoid using too much lubricant to prevent it from attracting dust.

- Reinstall the drawer: Once cleaned, put the drawer back on the slide and test whether it opens and closes smoothly.

Regular cleaning and lubrication can extend the life of the slide and keep it in optimal performance.

How do you make heavy wooden drawers slide easier?

To make wooden heavy duty drawer slides more easily, you can take the following measures:

- Check alignment: Make sure the drawer and heavy duty drawer slides are aligned correctly without any tilt or imbalance.

- Clean the slides: Clean the dust and dirt on the heavy duty drawer slides regularly to keep the heavy duty drawer slides clean and ensure smooth sliding.

- Lubrication: Apply a suitable lubricant (such as silicone grease or lubricating oil) to the sliding surfaces of the slides and drawers to reduce friction.

- Add slides: Install slides (such as plastic or wooden slides) on the bottom or sides of the drawer to reduce friction with the cabinet.

- Adjust the weight: Make sure the weight of the items in the drawer is evenly distributed and not overloaded. Overweight drawers may cause sliding difficulties.

- Check the quality of the heavy duty drawer slides: Use high-quality heavy duty drawer slides or strengthen existing slides to increase load-bearing capacity and smooth sliding.

These measures will help improve the sliding performance of wooden heavy duty drawers and ensure their smooth use.

What screws for heavy duty drawer slides?

When installing heavy duty drawer slides, it is important to choose the right screws to ensure the slide’s stability and load-bearing capacity. Here are some tips for choosing screws:

1. Screw Type:

Self-Tapping: For wood installation, suitable for heavy-duty slides because they can drill and tap in the wood without pre-drilling.

Machine Screw (with Nut): For metal or plastic slide installations that require higher load-bearing capacity, especially when higher strength and stability are required.

2. Screw Specifications:

Diameter: Choose screws with larger diameters (such as #8 or #10) to provide greater support and stability.

Length: Choose the appropriate length based on the thickness of the slide and the depth of the installation material. Generally speaking, the screw length should be at least 2-3 times longer than the thickness of the slide to ensure a secure fixation.

3. Material:

Stainless steel screws: For environments where they may be exposed to moisture or water, stainless steel screws can prevent rust.

Zinc-plated screws: In general environments, galvanized screws provide good strength and corrosion resistance.

4. Installation Notes:

Pre-drilling: If using self-tapping screws, especially for harder wood or MDF, pre-drilling can prevent the wood from cracking.

Even installation: Make sure the screws of the slide are evenly distributed to avoid deformation or loosening of the slide due to uneven force.

Correct selection and installation of screws can ensure the stability and long-term service life of heavy duty drawer slides.

Contact Us