Cold-rolled Steel Drawer Slides

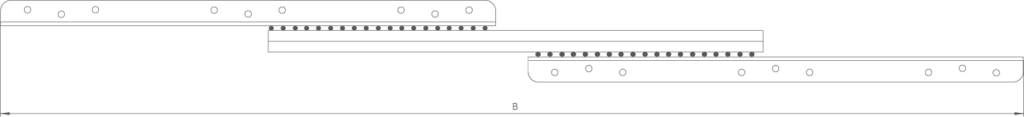

Heavy Duty Undermount Drawer Slides A2047

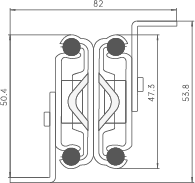

- Width: 48mm

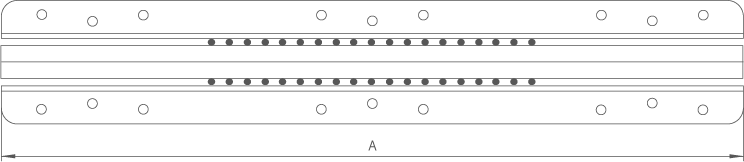

- Size Range: 400, 600, 800, 1000mm

- Material: Cold-rolled Steel

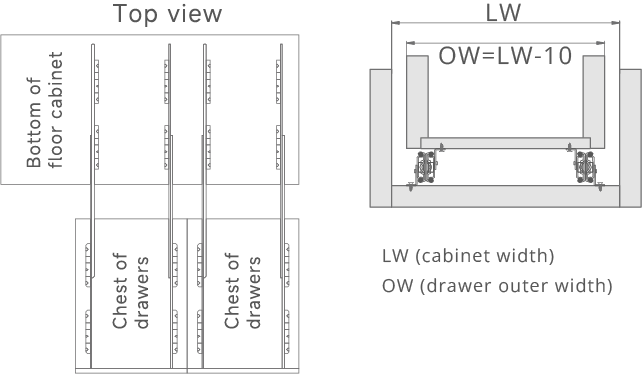

- Installation Gap: 54±0.3mm

- Loading Capacity: 120KG

- Material Thickness: 2.0*2.0mm

- Level of Travel: Full Extension

If you need customization, please contact us (+86)18126638650 or email info@censohardware.com

Tech Specs

—— Click on the customization option you need and contact us! ——

Size Chart

| A | B |

|---|---|

| 400 | 700/900 |

| 600 | 1100/1450 |

| 800 | 1500/1850 |

| 1000 | 1900/2250 |

| Support customized size | Support customized size |

Benefits of Partnering With CenSo for Drawer Slides

- Excellent Technology: Our 20+ R&D engineers use 15+ years of design and development experience to develop solutions for your project.

- Flexible Design: Besides providing a wide range of off-the-shelf products, we can customize various slide contents to adapt them to your project plan.

- Continuous Service: The entire CenSo team is committed to being your best partner. We will provide follow-up technical support on slides to ensure that your project is worry-free.

- Quality Assurance: Our drawer slides will be tested for 50,000 pulls and pulls at full load and 48 hours of salt spray test. We will also add corresponding tests according to the slides of different applications

faq

What wood can hold the most weight?

When using heavy duty drawer slides, you also need to choose a wood that can withstand more weight, which requires considering the strength, density, and durability of the wood. Here are some common types of wood with higher strength:

Hardwoods

Hardwoods are generally stronger than softwoods and are suitable for bearing more weight. Common hardwoods include:

Oak: Very durable, with good strength and hardness, suitable for load-bearing furniture.

Walnut: High density and high strength, suitable for high-end furniture and heavy structures.

Cherry: Although softer, it still provides good strength and stability, suitable for heavy-duty uses.

Maple: High hardness and wear resistance, suitable for a variety of furniture and load-bearing structures.

Softwoods

Although softwoods are generally not as strong as hardwoods, some types of softwoods can still withstand a lot of weight:

Red pine: Moderate strength, high density, suitable for load-bearing structures and furniture.

Cedar: Durable and high strength, suitable for buildings and exterior structures.

Factors to consider when choosing wood:

1. Density and hardness: The higher the density, the stronger the load-bearing capacity of the wood is generally. Hardness also affects the durability and load-bearing capacity of the wood.

2. Grain and structure: Wood with straight grain is generally stronger. Avoid wood with cracks, knots, or other defects.

3. Treatment and drying: Well-dried wood is stronger than wet wood. The way the wood is treated can also affect its strength and stability.

When choosing wood for load-bearing, make sure the quality of the wood is suitable for your heavy duty drawer slides needs, and consider consulting with a professional to ensure that the most appropriate type of wood is selected.

How do you fit heavy duty drawer slides?

To install the heavy duty drawer slides, follow these steps:

1. Measure and mark:

Measure the dimensions of the drawer and cabinet, mark the installation position of the slide, and ensure horizontal alignment.

2. Install the track:

Side-mounted slide: Fix one side of the slide to the side of the drawer and the other side to the inside of the cabinet. Make sure the track is level and secure with screws.

Bottom-mounted slide: Install the slide at the bottom of the drawer and the bottom of the cabinet, ensuring symmetrical alignment and securement.

3. Adjustment:

Check the alignment of the slide to ensure that the drawer can slide smoothly into the slide. Make fine adjustments if necessary.

4. Lubricate:

Add an appropriate amount of lubricant to the slide to ensure smooth sliding.

5. Test:

After installation, open and close the drawer repeatedly to ensure that the slide works properly and can bear the weight.

During installation, refer to the installation instructions of the slide and use appropriate tools and accessories to ensure a stable and reliable installation.

What is stair slide with buffer cabinet guide rail?

Stair slide with buffer cabinet guide rail is a kind of rail system designed for stairs and ramps, usually used on stair furniture or mobile equipment (such as trolleys, drawers or goods on stairs). The role of the buffer is to slow down the sliding process, ensuring that the rail works smoothly and quietly during use, avoiding collisions and noise.

What is the main purpose of stair heavy duty undermount drawer slides?

The main purpose of heavy duty undermount drawer slides for stairs is to help objects or equipment move smoothly and conveniently on stairs. Common applications include:

- Trolleys on stairs: such as cargo moving carts, luggage carts, etc.

- Stair drawers: storage drawers used under stairs to facilitate the storage of items.

- Assistive devices for the disabled: such as devices that help people with limited mobility to go up and down stairs smoothly.

- Furniture in home and office environments: such as drawers, cabinets, or equipment next to stairs.

How do stair heavy duty undermount drawer slides work?

Stair heavy duty undermount drawer slides work by providing a smooth, stable path for sliding on stairs. Depending on the design of the stair heavy duty undermount drawer slides, stair heavy duty undermount drawer slides may use rollers, guides, or pneumatic systems to support and guide objects moving on the stairs. Stair heavy duty undermount drawer slides may also come with bumpers or damping devices to help reduce the impact and noise of objects sliding.

Are stair heavy duty undermount drawer slides suitable for all stair types?

The suitability of a stair heavy duty undermount drawer slides depends on the design of the staircase and the type of rail system. Most stair heavy duty undermount drawer slides are suitable for standard stairs, but for very steep or very narrow stairs, a custom rail system may be required. In addition, the width, depth and slope of the stairs will affect the installation and use of the rail, so you need to make sure the rail is compatible with the stairs when choosing.

Contact Us