Cold-rolled Steel Drawer Slides

Industrial Drawer Slides A2576

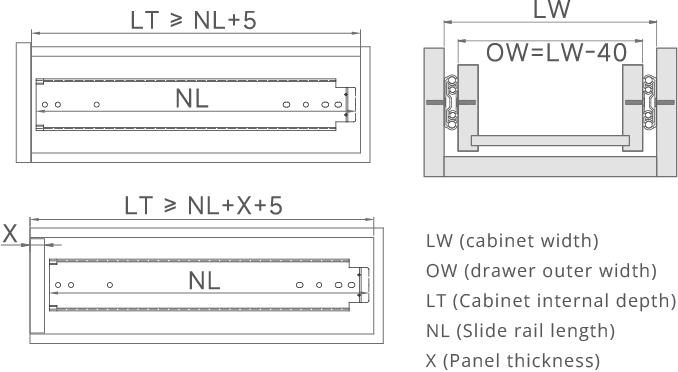

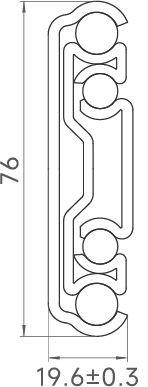

- Width: 76mm

- Size Range: 10″ to 60″

- Material: Q235 Cold-rolled Steel

- Installation Gap: 19.6±0.3mm

- Loading Capacity: 220KG/18″ (450mm)

- Material Thickness: 2.5*2.2*2.5mm

- Level of Travel: Full Extension

If you need customization, please contact us (+86)18126638650 or email info@censohardware.com

Tech Specs

—— Click on the customization option you need and contact us! ——

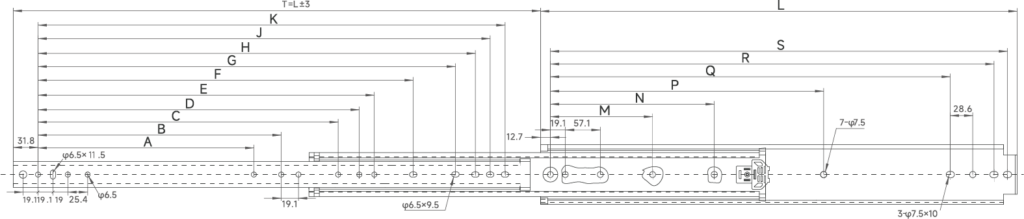

Size Chart

| Model | L | A | B | C | D | E | F | G | H | J | K | M | N | P | Q | R | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10" | 254 | / | / | / | / | / | / | 103.1 | 128.5 | 147.6 | 166.6 | / | / | / | 152.4 | 209.6 | 228.6 |

| 12" | 304.8 | / | / | / | / | / | / | 153.9 | 179.3 | 198.4 | 217.4 | / | / | / | 203.2 | 260.4 | 279.4 |

| 14" | 355.6 | / | / | / | / | / | / | 204.7 | 230.1 | 249.2 | 268.2 | / | / | / | 254 | 311.2 | 330.2 |

| 16" | 406.4 | 127 | / | / | / | / | / | 255.5 | 280.9 | 299.9 | 319 | / | / | / | 304.8 | 361.9 | 381 |

| 18" | 457.2 | 127 | / | / | / | / | 246.1 | 306.3 | 331.7 | 350.8 | 369.8 | / | / | / | 355.6 | 412.8 | 431.8 |

| 20" | 508 | 127 | 190.5 | / | / | / | 296.9 | 357.1 | 382.5 | 401.6 | 420.6 | / | / | / | 406.4 | 463.6 | 482.6 |

| 22" | 558.8 | 127 | 190.5 | / | / | / | 347.7 | 407.9 | 433.3 | 452.4 | 471.4 | / | / | / | 457.2 | 514.4 | 533.4 |

| 24" | 609.6 | 127 | 190.5 | / | / | / | 398.5 | 458.7 | 484.1 | 503.2 | 522.2 | / | / | / | 508 | 565.2 | 584.2 |

| 26" | 660.4 | 127 | 190.5 | / | / | / | 449.3 | 509.5 | 534.9 | 553.9 | 573 | / | / | / | 558.8 | 615.9 | 635 |

| 28" | 711.2 | 127 | 190.5 | / | / | / | 500.1 | 560.3 | 585.7 | 604.8 | 623.8 | / | / | / | 609.6 | 666.8 | 685.8 |

| 30" | 762 | 127 | 190.5 | 368.3 | / | / | 550.9 | 611.1 | 636.5 | 655.6 | 674.6 | 234.9 | / | 501.6 | 660.4 | 717.6 | 736.6 |

| 32" | 812.8 | 127 | 190.5 | 368.3 | / | / | 601.7 | 661.9 | 687.3 | 706.4 | 725.4 | 234.9 | 393.7 | 552.5 | 711.2 | 768.4 | 787.4 |

| 34" | 863.6 | 127 | 190.5 | 368.3 | 469.9 | / | 652.5 | 712.7 | 738.1 | 757.2 | 776.2 | 234.9 | 419.1 | 603.3 | 762 | 819.2 | 838.2 |

| 36" | 914.4 | 127 | 190.5 | 368.3 | 520.7 | / | 703.3 | 763.5 | 788.9 | 808 | 827 | 234.9 | 444.5 | 654.1 | 812.8 | 870 | 889 |

| 38" | 965.2 | 127 | 190.5 | 368.3 | 520.7 | / | 754.1 | 814.3 | 839.7 | 858.8 | 877.8 | 234.9 | 469.9 | 704.9 | 863.6 | 920.8 | 939.8 |

| 40" | 1016 | 127 | 190.5 | 368.3 | 520.7 | / | 804.9 | 865.1 | 890.5 | 909.6 | 928.6 | 234.9 | 495.3 | 755.7 | 914.4 | 971.6 | 990.6 |

| 42" | 1066.8 | 127 | 190.5 | 368.3 | 520.7 | 723.9 | 855.7 | 915.9 | 941.3 | 960.4 | 979.4 | 234.9 | 520.7 | 806.5 | 965.2 | 1022.4 | 1041.4 |

| 44" | 1117.6 | 127 | 190.5 | 368.3 | 520.7 | 723.9 | 906.5 | 966.7 | 992.1 | 1011.2 | 1030.2 | 234.9 | 546.1 | 857.3 | 1016 | 1073.2 | 1092.2 |

| 46" | 1168.4 | 127 | 190.5 | 368.3 | 520.7 | 723.9 | 957.3 | 1017.5 | 1042.9 | 1062 | 1081 | 234.9 | 571.5 | 908.1 | 1066.8 | 1124 | 1143 |

| 48" | 1219.2 | 127 | 190.5 | 368.3 | 520.7 | 825.5 | 1008.1 | 1068.3 | 1093.7 | 1112.8 | 1131.8 | 234.9 | 596.9 | 958.8 | 1117.6 | 1174.8 | 1193.8 |

| 50" | 1270 | 127 | 190.5 | 368.3 | 520.7 | 825.5 | 1058.9 | 1119.1 | 1144.5 | 1163.6 | 1182.6 | 234.9 | 596.9 | 958.8 | 1168.4 | 1225.6 | 1244.6 |

| 52" | 1320.8 | 127 | 190.5 | 368.3 | 520.7 | 825.5 | 1109.7 | 1169.9 | 1195.3 | 1214.4 | 1233.4 | 234.9 | 596.9 | 958.8 | 1219.2 | 1276.4 | 1295.4 |

| 54" | 1371.6 | 127 | 190.5 | 368.3 | 520.7 | 825.5 | 1160.5 | 1220.7 | 1246.1 | 1265.2 | 1284.2 | 234.9 | 596.9 | 958.8 | 1270 | 1327.2 | 1346.2 |

| 56" | 1422.4 | 127 | 190.5 | 368.3 | 520.7 | 825.5 | 1211.3 | 1271.5 | 1296.9 | 1316 | 1335 | 234.9 | 596.9 | 958.8 | 1320.8 | 1378 | 1397 |

| 58" | 1473.2 | 127 | 190.5 | 368.3 | 520.7 | 825.5 | 1262.1 | 1322.3 | 1347.7 | 1366.8 | 1385.8 | 234.9 | 596.9 | 958.8 | 1371.6 | 1428.8 | 1447.8 |

| 60" | 1524 | 127 | 190.5 | 368.3 | 520.7 | 825.5 | 1312.9 | 1373.1 | 1398.5 | 1417.6 | 1436.6 | 234.9 | 596.9 | 958.8 | 1422.4 | 1479.6 | 1498.6 |

Benefits of Partnering With CenSo for industrial Drawer Slides

- Excellent Technology: Our 20+ R&D engineers use 15+ years of design and development experience to develop solutions for your project.

- Flexible Design: Besides providing a wide range of off-the-shelf products, we can customize various 316 stainless steel drawer slides contents to adapt them to your project plan.

- Continuous Service: The entire CenSo team is committed to being your best partner. We will provide follow-up technical support on slides to ensure that your project is worry-free.

- Quality Assurance: Our drawer slides will be tested for 50,000 pulls and pulls at full load and 48 hours of salt spray test. We will also add corresponding tests according to the slides of different applications.

faq

What makes drawers slide better?

Factors that make drawers glide more smoothly include:

1. Drawer slides type and quality

High-quality drawer slides: High-quality drawer slides systems reduce friction and make drawers glide more smoothly.

Soft-closing mechanism: Some drawer slides systems are equipped with a soft-closing function to ensure that the drawer closes smoothly and slowly without jamming.

2. Lubrication

Proper lubricant: Use lubricants such as graphite powder, silicone oil, or wood wax oil to reduce friction and make the drawer glide more smoothly.

Regular application: Check and reapply lubricant regularly to maintain smooth sliding.

3. Cleaning

Remove dust and debris: Clean the drawer slides and drawer grooves to remove dust and debris to prevent them from causing resistance.

4. Alignment and adjustment

Proper alignment: Make sure the drawer and drawer slides are aligned to avoid jamming caused by misalignment.

Adjusting screws: Check and adjust the screws of the slide to ensure that the slide is stable and aligned.

5. Check the load

Appropriate load: Avoid overloading the drawer. A heavy drawer will affect the sliding effect.

6. Wood condition

Wood dryness: Make sure the wood does not expand due to changes in humidity and affect sliding. If necessary, light grinding can be performed to improve the sliding effect.

7. Drawer slides maintenance

Regular inspection: Regularly check the wear of the drawer slides and repair or replace damaged drawer slides in time.

Summary

By using high-quality drawer slides, regular lubrication, keeping them clean, ensuring correct alignment, reasonable load, and regular maintenance, the sliding performance of the drawer can be significantly improved and made smoother.

Should you mount drawer slides high or low?

The height at which you install drawer slides depends on the design and use requirements of the drawer, but it is generally recommended to decide based on the following principles:

1. Design and functional requirements

Low installation: For most home furniture and filing cabinets, slides are usually installed at the bottom of the drawer. This helps maintain the stability and support of the drawer and makes the drawer smoother when opened.

High installation: In some cases, such as using shallow drawers or specially designed furniture, slides may be installed on the side or higher position of the drawer. This setting can save space, especially in compact furniture or drawers used for specific functions.

2. Stability and load-bearing

Bottom installation: Bottom installation usually provides better stability and load-bearing capacity. When the slide is installed at the bottom of the drawer, the weight of the drawer is more evenly distributed on the slide, reducing sliding problems caused by uneven weight.

Side installation: If the drawer slide is installed on the side of the drawer, it usually increases the load capacity of the slide and is suitable for drawers that need to bear a larger weight.

3. Aesthetics and function

Visual effect: Bottom-mounted slides are usually more concealed and do not affect the appearance of the drawer. Side-mounted slides may be more visible but can provide more space utilization options.

4. Convenient to use

Easy to maintain: Bottom-mounted slides are easier to maintain and clean because the contact surface between the slide and the drawer is more accessible at the bottom.

Summary

Bottom mounting is usually the standard practice for most home furniture because it provides better stability and load capacity. However, the specific installation height should be determined based on furniture design, functional requirements, and aesthetic considerations. If you are unsure, it is a good choice to refer to the slide manufacturer’s recommendations or consult a professional.

How do you slide heavy furniture easily?

When sliding heavy furniture, you can use the following methods to make it easier and protect your floors:

1. Use furniture glides

Glides: Place furniture glides on the bottom of the furniture. These glides are usually made of plastic, rubber, or fiber. They can reduce friction and make the furniture slide more easily.

Type: Choose the right glides for the type of floor (such as wood, tile, or carpet) to ensure the best results.

2. Use furniture moving tools

Furniture pulleys: Furniture pulleys are tools specially designed to move heavy objects, which can easily slide furniture from one location to another.

Furniture dollies: Dollies are equipped with wheels to support heavy furniture and make it easier to slide.

3. Use leverage

Pry bars: Use pry bars or heavy tools as levers to lift a piece of furniture, and then place glides or other supports under the furniture.

Wooden blocks or bricks: Place small wooden blocks or bricks under the furniture to gradually raise the furniture and make it easier to slide.

4. Lubricate the floor

Floor lubrication: Lightly spray some lubricant (such as soapy water or silicone oil) on the floor to reduce friction and make the furniture slide more easily. Be sure that the lubricant does not damage the floor.

Lubricate under the carpet: If there are plastic mats under the carpet, cleaning and maintaining the sliding properties of these mats can also help move heavy furniture.

5. Move in steps

Move-in steps: Divide the process of moving the furniture into several steps, first gently lift one end, place a glide pad or support, and then move the other end. This can reduce pressure and friction on the floor.

6. Assistance tools

Carrying straps: Use special carrying straps to lift and slide the furniture. The design of the carrying strap can help two people coordinate their movements and reduce the burden of carrying.

7. Protect the floor

Protective mats: Place protective mats or cloths on the area where the furniture is moved to protect the floor from scratches or damage.

Check the condition of the floor: Make sure there are no protruding nails or dirt on the floor, which may affect the movement of the furniture.

8. Ask for help

Teamwork: For particularly heavy or large pieces of furniture, it is best to have two or more people work together to ensure safety and effectiveness.

Summary

To easily slide heavy furniture, use furniture glides, furniture wheels, or dollies, leverage to reduce the load, and lubricate the floor to reduce friction. Moving furniture gradually, protecting the floor, and asking for help are also key steps. With these methods, heavy furniture can be moved effectively while protecting the furniture and the floor.

Contact Us